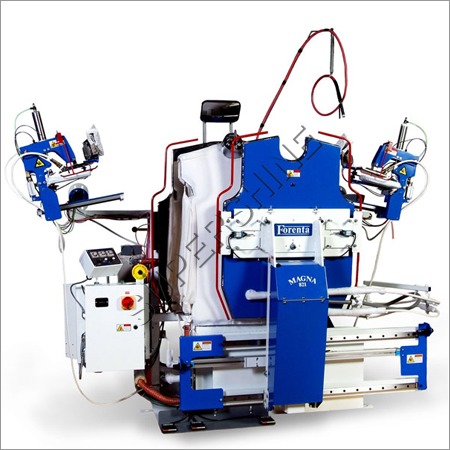

Forenta Dry Cleaning Utility Press

Price 100000 INR/ Piece

Forenta Dry Cleaning Utility Press Specification

- Fabric width

- Up to 36 inches

- Manufacturing Year

- 2024

- Machine Type

- Utility Press

- Control System

- Manual & Automatic

- Weight

- 185 kg

- Production Capacity

- 120-150 pieces/hour

- Type

- Dry Cleaning Utility Press

- Pressure Range

- 30-50 psi

- Fabric Type

- Plastic

- Drive Type

- Pneumatic

- Applicable Material

- Plastic And Metal

- Drying Method

- Pressing

- Working Width

- 36 inches

- Heat Source

- Electric

- Features

- Quick heating, Energy-efficient, Safety lock, Durable construction

- Temperature Range

- 150C - 200C

- Dimension (L*W*H)

- 1400 x 900 x 1600 mm

- Speed

- Variable according to operation

- Noise Level

- Low (<70 dB)

- Voltage

- 120 Volt (v)

- Auto Shut Off

- Yes

- Color

- White and Blue

- Compressed Air Requirement

- 90-110 psi

- Installation Type

- Floor mounted

- Cycle Time

- 15-30 seconds per piece

- Platen Material

- High-grade coated steel

- Usage/Application

- Commercial dry cleaning

- Power Consumption

- 3.8 kW

- Safety Features

- Emergency stop button, heat safety shield

- Humidity Control

- No

- Control Panel

- Digital display with preset programs

- Packaging Type

- Wooden box

Forenta Dry Cleaning Utility Press Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Central America, South America, North America, Africa

- Main Domestic Market

- All India

About Forenta Dry Cleaning Utility Press

Our company is a quality approved manufacturer of Forenta Dry Cleaning Utility Press. These hi tech laundry equipment, crafted with the aid of advanced engineering techniques, are acknowledged for their greater longevity and immaculate performance. They are convenient to install and operate. Available in different customized forms, our equipment are strictly tested on quality grounds for ensuring optimum results to the end users.

Attributes :

- Low maintenance ccost

- Competitive price

- Safe and reliable

- Quick and efficient

Advanced Control for Precision Pressing

Operate with confidence using the digital display and preset program features of the Forenta Utility Press. Both manual and automatic options enable tailored use in busy commercial settings, optimizing efficiency during each cycle. The floor-mounted design and variable speed settings ensure adaptability for a range of pressing operations.

Robust Safety and Durable Construction

Built with high-grade coated steel and equipped with essential safety features such as an emergency stop button and heat safety shield, this utility press prioritizes operator protection. The sturdy construction and quality materials provide long-term reliability, while the low noise output guarantees a comfortable working environment.

FAQs of Forenta Dry Cleaning Utility Press:

Q: How is the installation of the Forenta Dry Cleaning Utility Press carried out?

A: The utility press is designed for floor-mounted installation, and it is packaged in a secure wooden box to ensure safe transport and delivery. Professional guidance is recommended to set up the machine in commercial dry cleaning facilities.Q: What materials and fabrics can be processed with this utility press?

A: The Forenta Utility Press is suitable for pressing plastic and metal applicable materials as well as fabrics up to 36 inches wide. Its durable platen is made from high-grade coated steel, ensuring consistent results across various items.Q: When should the emergency stop feature be used on the utility press?

A: Use the emergency stop button whenever an unsafe condition occurs during operation, such as a malfunction or unexpected event. This safety feature is designed to immediately halt the pressing cycle and protect the operator.Q: Where is the control panel located and what features does it offer?

A: The control panel is conveniently positioned on the machine and includes a digital display with preset programs, allowing operators to customize settings for different pressing requirements and fabrics.Q: What is the process and typical cycle time for pressing with this machine?

A: Each pressing cycle usually takes between 15 and 30 seconds per piece. The process involves activating the press, selecting settings via the digital panel, and using the pneumatic drive to perform efficient and uniform pressing.Q: How does auto shut off benefit users during operation?

A: The auto shut off feature helps users save energy and adds an extra layer of safety by automatically switching off the machine after a period of inactivity or at the end of a pressing cycle, reducing risk and improving operational efficiency.Q: What are the benefits of using the Forenta Utility Press in commercial dry cleaning?

A: Key benefits include high production speed (up to 150 pieces per hour), energy-efficient operation, low noise levels, advanced safety features, and reliable performance. These advantages make the press ideal for busy dry cleaning businesses seeking consistent, high-quality results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Finishing Equipments Category

Hot Head Press

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Applicable Material : Plastic And Steel

Condition : 1

Type : Head Press

Voltage : 220240 Volt (v)

Rotary Double Body & Sleeve Press

Price 110000 INR / Unit

Minimum Order Quantity : 1 Unit

Applicable Material : Plastic And Steel

Condition : 1

Type : Double Body & Sleeve Press

Voltage : 220240 Volt (v)

Flatbed Press Machine

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Applicable Material : Plastic

Condition : 1

Type : Stacker Machine

Voltage : 220240 Volt (v)

Body Sleeve Press

Price 100000 INR / Piece

Minimum Order Quantity : 1 Unit

Applicable Material : Plastic And Metal

Condition : 1

Type : Sleeve Press

Voltage : 120440

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free